üĪStructure of LTPS-TFT-LCD

ć@Single drain structure (SD)

ćADual Gate structure

ćBLDD (Lightly Doped Drain) structure

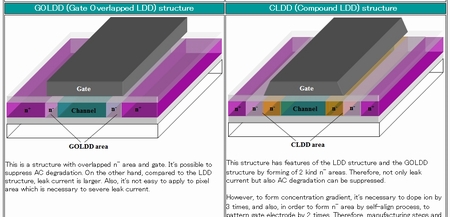

ćCGOLDD (Gate Overlapped LDD) structure

ćDCLDD (Compound LDD) structure

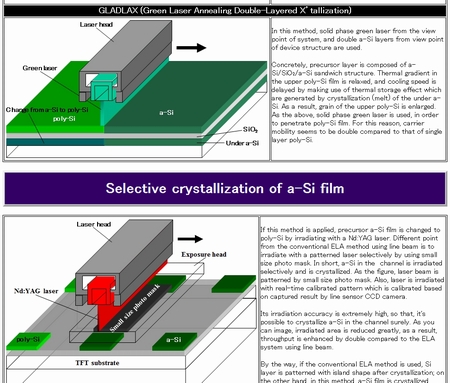

üĪCrystallization process

üĪTFT array process

ć@Single drain structure (SD)

ćALDD (Lightly Doped Drain) structure

ćBGOLDD (Gate Overlapped LDD) structure

ü@

Forming process of poly-Si

ü@

Forming process of TFT area (PEP1)

ü@

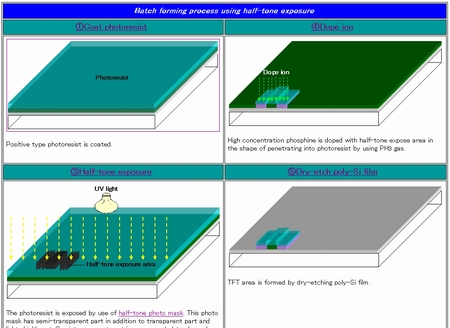

Batch forming process of S/D in TFT area and N-channel (PEP1)

ü@

High concentration P doping process (PEP2)

ü@

Forming process of gate electrode and capacitor electrode (PEP3)

ü@

P-TFT High concentration N doping process (PEP4)

ü@

Forming process of contact hole (PEP5)

ü@

Forming process of data line (PEP6)

ü@

Hydrotreatment, form passivation and planarization layer (PEP7)

ü@

Manufacturing process of pixel electrode (PEP8)

ü@

P-TFT ion doping process

ü@

N-TFT ion doping process

üĪCF (Color filter) forming process

ü@

Manufacturing process of CF for IPS mode/FFS mode TFT-LCD

ü@

Manufacturing process of CF for VA mode TFT-LCD

ü@

Manufacturing process of CF for TN/OCB mode TFT-LCD

ü@ü@

Black matrix forming process

ü@ü@

Manufacturing process of R, G, B color layer

ü@ü@

Manufacturing process of overcoat layer

ü@ü@

Deposition process of opposite electrode

ü@ü@

Manufacturing process of post-spacer

ü@ü@

Manufacturing process of rib (bump)

ü@ü@

Photo-alignment process (for MVA mode TFT-LCD)

üĪLC cell process

ü@

Polyimid coating process

ü@

Alignment process

ü@

Seal layer forming process

ü@

Dispersion process of spacer-ball

ü@

Making panel thinner process

ü@

Scribe and break process

ü@

Filling process of LC material

ü@

ODF (One drop fill) process

üĪModule assemble process

ü@

Connect panel and driver-IC

üĪLiquid crystal material and display mechanism

üĪStructure of backlight module

üĪ3D technology

Method to use a specific glasses

ü@

LC shutter glasses method (Time sequential method)

ü@

Polarized glasses ü{ patterned phase difference film (Space division method)

Specific glasses-free method

ü@

Parallax barrier method

ü@

Parallax barrier using dual emission OLED

ü@

Time sequential driving ü{ parallax LC barrier method

ü@

Lenticular lens method

ü@

Time sequential twin-lens 3D-OCB method

ü@

Lenticular ü{ time sequential scanning backlight method

Detail of material and system is explained |