■Explain CNT-TFT manufacturing process by illustration

■Full-cover from basic process to next generation process

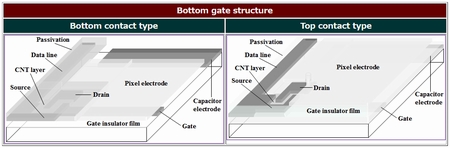

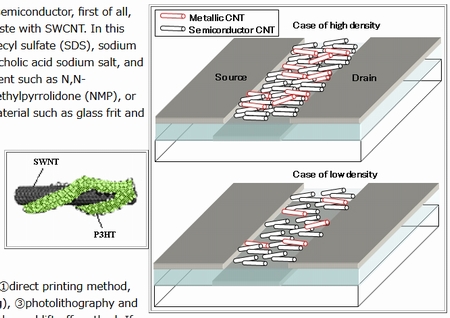

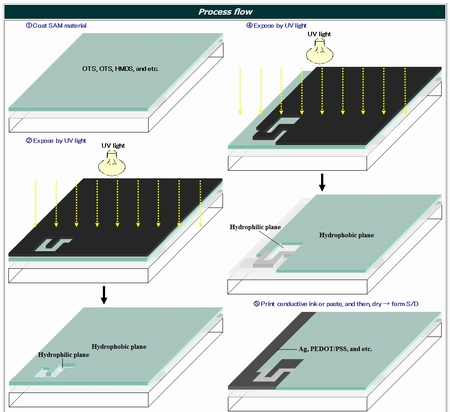

■Cover structure, substrate, material, and manufacturing process

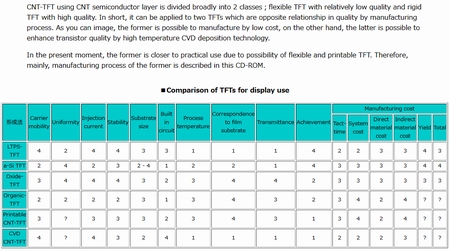

■Clearly difference of printable TFT and high quality TFT, which are main kinds of CNT-TFT

■In the CNT semiconductor layer process, the detail processes from pre-treatment to CVD/wet coating process are explained

■Easy to look at the file using any PC because of the format of browser, for example IE (Internet Explorer)

■Possible to access at will from Index Page to detail page

■Describe these illustrations at 3D image

■Number of total file are 35 (about 80 page in A4 form equivalent)

■Illustrations of device structure and process flow are approximately 190.